So this is all going to be 3d printed mods I have already done a 35hr print on the control board side I have printed the new feet need to print the SSR module clip might set that up whilst I am remote in wales the joys of being connected. so all I will need to do is 2 lids then will be ready for the pro upgrade.

also mounting on the screen on the side of the machine. might need to reprint the printing bracket. as want it on the left-hand side of the machine.

so just uploaded it to the local computer and now have kicked off the amazingly long 23min print haha so will only be 2 x 7hr prints left when I get home on Monday. just as I feared the small print it failed never mind noticed and cancelled the print. will check back with the main print later.

wow, that’s the long prints done now for some smaller prints and armed with elnet the king of hair spray when it comes to getting prints to stick well. as Pritt stick is too messy. wow just saw the bend in the heat bed how did that happen bent it flat again. just going to adust the bed by probe till it’s nearly on the money then I might lock tight them in position for the moment. probably should have done that before I kicked off an 8hr print.

I will be going over to a flexible steel bed soon but till then I am going to continue on the old fashion way well till the credit card bill rolls and I then have my monthly spending pot.

so smooth a 4hrs to go.

think its dialed in now.

starting to get ready for build

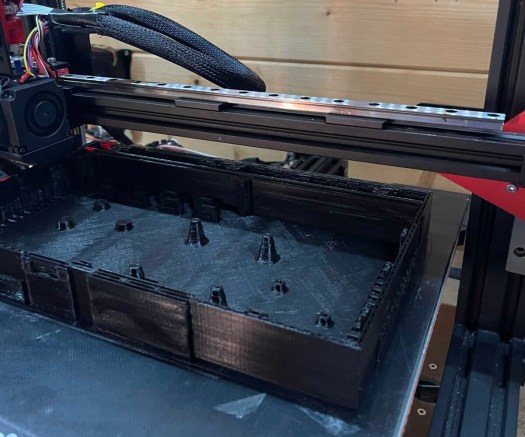

lids and SSR printed and that just under 1kg of filament was done. on the case.

All parts printed for pro conversion

last time it will look like this

so time to strip out the old box and fit the electronics in the new one oh and to add the new feet so it will fit.

just need to order some silent fans as the control box fan is really annoyingly loud so I have orderd 120mm nocturia fan and I think i will need to order 80mm one for the PSU supply. I will be opening that up in the rebuild as one i dont know its voltage and 2 pin numbers 2 or 3 so will order that when i konw.. I then have to think about speed control as i don’t think they need 100% speed but that I will be looking into as we go, as going to monitor temprature with a probe in the electronics low voltage box.

Have been thinking about a name for my cr-10 modified machine that came up with cave monster. so the next round of modifications to the code will include a name change haha. will attempt to design him a logo as well for the boot screen.

as i have been spending alot of time getting everything printed for the next step i have been customising my octoprint layout and feel. also on christmas crafting for friends and family so yes been a fun week that and i am re jigging the work shop as need to add storage for extra tools as need to make it all work.

High voltage side.

time to look at power supply and lable up wring before i strip it out the box. next up power input and switch. I will be making new wiring for all power elements. First up adding the mains power plug and switch. looks like the are going to need a little help fitting so out with the dremal and they now fit. as it cold have stopped halfway through the job as working how and where to route the wiring and fit the ssr to the psu.

Heat Bed mains and switch in

now to figure out this mess

all high voltage done.

Also, going to wire the printer PSU through a 5v relay so i can turn the printer on and off through the raspberry pi cover this in the Low voltage side of the board but will cover that later.

Low voltatge side.

Now i have the power run across the board I will either add the bucks converter to step the 12v down to 5v to run the raspberry pi or I will use a mains adapter this will allow me to shut down the printer where as the other way would be a total power off. whilst I think I will install the pi and the main control board. am then going to install 2-way relay board so i can switch on/off the machine and lights via the relay.

boards in ready for wires

final image for refrence.

need to think about this as big arse fan wil be above this.

Might run the wiring under the main board to keep it away or i mgiht just exstend the wiring.

Time to connect all the power wires and the heater wiring to the board and the SSR.

Now to add all the board inputs and output so end stops motors and sensor

next, it is time to fit the 120mm fan to keep things cool as its a 4 pin I will only use the 12v supply as should work will test this theory later also waiting on t-nuts so I can bolt this to the frame should have them later on today so will finish wiring ready to bolt it all together.

got one more print to go on as adding halo light to the camera so I can film all the loverly creations that I am making with the printer but that will be done once I have installed the rest of the electronics. going to make the camera mount a little more sensible as i feared there’s a little bit of a wobble when running.

As I am waiting on parts as amazon let me down I will be getting the last bits sorted ready to bolt the boxes to the bottom of the printer. ok been a week had a family issue that’s now come to a sad conclusion. so back in London will try wrapping this stage up by Xmas but see what happens.

How my plans have changed

its been 2 weeks of hell over Xmas father in law passed away suddenly so was in wales for a week then came back to london and wife and son both have covid so stuck in london in the house i am negtive and they are both ok.

bad new but good news been working on the project and ironing out my kinks with it so where to start

It dont fit under my printer bed like its ment to due to my custom bed so instead of having a hissy fit throw 70 hrs printing. I am going to let be and will figure it out as i go i have welded the 2 sides together with some high strength glue and exsellitator now bonded together

custom mounts piot holes drilled.

now to screw it in place.

stand offs in and board scured.

relays all wired up.

New power for lights and speed conroller wired up.

All in working

i then have added some custom stand offs for the fan speed controler and 2 channel relay. i then drilled holes for external raspberry pi power and for fan controler knob. oh and power connector for the halo.

bit of wiring changes to the printer can be powerd off and on by the raspberry pi also using the 12v psu to power the halo light as well also had to change the wiring.

and we are good to go i am waiting on the next mods to show up from the far east got one PCB board still to fit so before i bolt it back together and start testing the new fetures

I will leave this here. get ready to part 5 this will be the final part i hope. so whats coming well a UPS 12v board from big tree tech. New fexable bed for the machine and fliminet runout sensor from big tree tech and upgraded linier rail upgrade and thats it.

i think after that i have run out of mods.

see you all in part 5.

You must be logged in to post a comment.