here’s is a list of tools I have printed and have found useful to help make create and fix issues in my workshop. these are all things I have tested and used in my workshop some have been featured by others but hay this is my definitive guide to what i am using in my workshop at the moment.

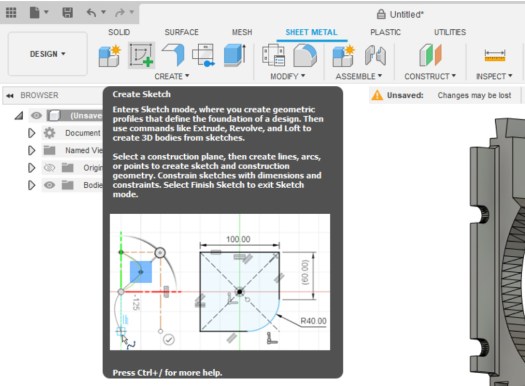

This is a great little quick print for finding out an unknown radius, great for 3d sketching or laser cutting objects.

2. Small Parts Funnel Tray by countspatula can be found here.

this is a must for workshops that have lots of small parts that they need to put in small draws. this is my go-to tool when I get boxes of screws in to sort into their draw project.

nice quick 1hr 32 to print nice and compact to store.

3. Airbrush Wall Mount Holder with Drip Trays & Anti-Tilt by cncartist file can be found here.

in my very small workshop means my airbrush is easy to access off this handy little wall mount.

4. Screwdriver bit wall mount by SaKes file can be found here

use this and its remixes for drill bits and all my quick release bits.

As you can see I have a whole collection of bits easy to access with these wall mounts.

5. Spray can wall mount by Isalvador file can be found here

great for clearing some more spaces off my shelves for more kit and tools got 8 cans mounted behind the cave monster might add more. as a nice quick print, any wall space is a game changer for extra space have since got carried away and done both sides of the racking.

6.Disposable Glove Holderby mkelly file can be found here

12h48 print but saved me around £15 buying one off amazon.

Been meaning to buy a glove holder to mount on the workshop wall, As I have a box of nirol gloves kicking round workshop covid/resin work/ resin printing etc and I found this box so 1 money was saved for the next creation.

Metric Screw Hex Nut byJigby HDRI file can be found here

Love this great for determining what size that bolt you need is within seconds just used this as had a screw was too long by 10 mm so placed it in the guide figured out it was a 40mm bolt and I needed 30mm also identified it was an m5 bolt I required. one for my small tools tray. great for sorting that box of mixed bolts I have kicking around.

Wall-mounted spanner holder8 pcs by DaFed file can be found here

more saving spaces in draws as every spare wall space is used in my workshop as it’s so small. found this the other week love it went for the 8pces version as just needed to clear some space from my toolbox and this worked for me.

there are more bits I’m currently printing and testing which I will add to this list in the near future

You must be logged in to post a comment.