Well, I have managed to do so bits in my spare five minutes here and there, Between looking after son and trying to get him into a routine. So we can have some time to do things we would like. so far it’s working but just a bit erratic.

I have built a PC to run the CNC controller software out of an old HP computer I had kicking in my office its nothing fancy will be running windows 7 and mach3 software provided with the machine. will cover this more when I do a review and set up a blog post soon. Already working on a waste board will be the first project I will run with the milling machine once all set up.

Have been running upgraded printed parts on my Prusa Mk3:

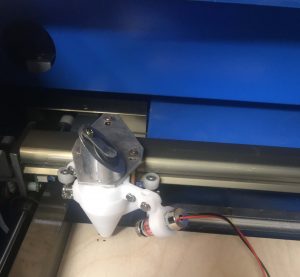

- Printed K40 laser pointer printed for 12mm laser crosshair diode to be added.

- Printed Dust extraction addon for my CNC machine.

- Printed Camara mount for Mk3 so can record some live-action / time lapses for future videos once I have some time to do some. family first.

Ordered parts:

- MDF for enclosure of my CNC machine and for a Waste board.

- Laminated Acrylic for the control panel for K40 Laser. (going to have to cut it down as size is a little larger than I thought. )

- 12mm Laser diode crosshair.

- New extraction fan for K40 laser exhaust as other one is less than strong enough and when I start cutting and engraving acrylic I don’t want to be breathing the fumes.

Parts I need to order in the near future:

- Perspex sheet for the front of the enclosure of CNC machine.

- rare earth magnets to hold the front door in place.

- A hinging mechanism for the front door of the enclosure.

- dust cyclone extractor for a vacuum system for CNC machine

- Water container for CNC machine cooler

- Vacuum cleaner to run the system

Upcoming projects:

CNC Enclosure will be using my racking and some MDF to make an enclosure with a perspex door.

Wast board for CNC machine this will allow me to clamp and grip parts for milling it will also be a damaged board so I can cut out pieces without damaging CNC bed,

K40 Cohesion3D Mini Upgrade, as you might have seen I have been designing a new control panel for this upgrade will be doing this around easter I would think as next period of time that I will have some free time.

You must be logged in to post a comment.