This is going to be a mammoth Post. Have been buying in bits for the last few weeks to get this machine all upgraded to the speck that I wanted for a while.

was just going to be the controller board upgrade but me being me anyway enjoy the post feel free to comment.

I have designed a new control panel few posts ago. I will be adding it, In this post and taking care of a few mods at the same time.

As my time is limited has taken me a week or so to do all this with an hour here an hour there when the son was sleeping.

Parts list:

- 1 x Custom Control Panel.

- 1 x C-13 Custom Panel.

- 3 x C-13 connectors female.

- 3 x C-13 connectors male.

- 3 x Power Led Buttons 240v rated. (Power on, Air assist and lighting)

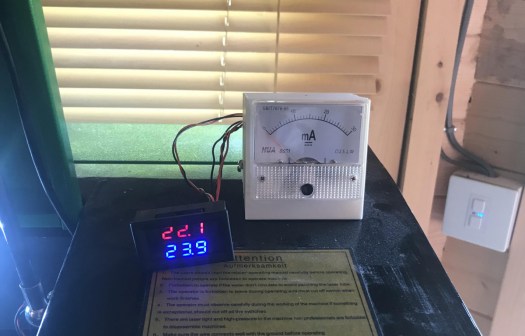

- 1 x mA meter from the original machine.

- 1 x mA pot from the original machine.

- 1 x 16mm push button latching switch LED 12v. (Laser On/Off Switch)

- 1 x 16mm push button momentary switch LED 12v. (Laser Test Switch)

- 4 x M3 x 25mm screws and M3 nuts.

- 1 x 5v 3amp power supply.

- 1 x 24v 10amp power supply.

- 1 x External Stepper driver 4 amp

- Mains wiring Live Neutral and earth I have allowed 3m of each.

- 1 x Cohesion3D Mini K40 Upgrade kit (including screen and lightburn software licence).

- 1 x 3d printed bracket for side mounting laser power supply.

- 8 x 3d printed spacer discs

- 5 x 3d Printed bed adapters.

- 1 x 3d Printed laser holder.

- 1 x 12mm Laser diode with a cross adapter.

- Updated laser mount plate.

- Steel wire mesh for a new bed.

- Bunch of m3 and m4 nuts and bolts

As I now have all parts in the mancave let’s kick this project off with printed parts

3D printed parts for a build:

I have printed sideways power supply mount, I sliced and printed on my Prusa i3 Mk3 took 5hr 12mins to print.

I will need to move the installed power supply sideways so I can add additional power supplies for the extra 24v and 5v power supplies I will be installing on my machine.

Link on Thingiverse

Bed adapter for wire mesh bed.

Next up on the printer was some bed adapters I printed five as that’s how many screws held down the alloy plate to my machine. The Thingiverse file can be found here.

Bed spacer discs for bed.

I also printed some bed spacers so I can hold materials off the bed. This mod requires some m3 nuts and m3 hex bolts I had some kicking around I printed 8 for good measure might print some more. I measured 6mm off base for cutting 3mm material as I know that’s where my focal is set on cutting head. Link for spacer discs on Thingiverse. These took around 1hr to print.

Update printing a box load as see image laser cuts them like butter but for the sake of 1hr print for 8 I don’t mind just run 16 spares.

Laser Sight adapter.

I took used two designs and combined them to make my laser sight. So the ball holder and bracket links below.. and the ball for 12mm laser diode.. you will also need an m3 x 30mm and m3 nut t tighten ball in place once in position. You will need 2 x 25mm m3 bolts and 2 x m3 nuts to hold it to plate. This was around 30 mins for the ball and think 1:40 for bracket all done with no supports.

Link for bracket

Link for laser ball (only use ball)

Cutting laminated acrylic to size:

Next up to cut out the final control panel I will need to cut down the material I ordered from 903 ltd it’s a laminated acrylic so white on the outside black in the middle.

I have made cutting jig using two hand clamps and a spirit level. I will score the acrylic and then snap it. I have done this to allow it to fit in cutter note to self-order small bits next time.

worked well now have a piece of acrylic around A4 size perfect for the panel.

Final Prototyping of control panel:

I then did a final prototype in plywood as had adjusted the holes locations and sizes and make sure all fitted correctly as cannot afford to waste material.

Good job I did one more test as I will have to do one more test cut panel mounts are 5mm out and laser on-off switch text gets covered by the top panel so will move that across at the same time.

This is why you do have to prototype again and again till its right

So what started off as some simple changes I decided to change the font of digits around the power gauge and align all text make two holes bigger on the control display knob and brightness adjustment holes, I then enlarge the panel mount holes as well. To make sure all fits. Version 5.2f Final Version. I will upload the design to Thingiverse Link Here

The Final cut in laminated acrylic

After reading the material guide on cutting and engraving which is based on 30watt or 50watt helpful when I own a 40watt laser I did do some experiment using a small offcut as I had a big board cut down to make smaller pieces.

My findings were.

Cutting the Acrylic, I found that 15 mA and speed of 4 mm/s cut through the acrylic like butter I probably could have dropped the mA might do some more testing on this at some point

Engraving the Acrylic, I found that 10 mA and speed of 100 mm/s I did run at 70 there was a little more scorch marks on my test see above image.

The Process I did cut pass first of all with the protective layer on I used double-sided tape to hold the acrylic in place on the bed on edges after the cut I removed the protective tape and cut parts. Then placed the cut piece back in cutout see images below. And run the engraving process. I also added furniture polish to the top layer this will help with cleaning after the process is completed.

I then uninstalled all switches and screen dial etc and moved them to the final resting before reinstalling control panel back in the machine.

I also cut a new back Panel for C13 Connectors that I had remixed to be labelled for the different outputs of the machine. this was test project so a lot more scorching but for the back of my machine, it’s perfect as won’t really be seen.

The Wiring:

Now the fun part wiring up the panel before I do the final cut in acrylic.

First off I re-install the mA meter, followed by mA pot,

Now to the additional two power switches and original switch. Using some crimps and mains wire I wired up a jumper cable that supplies power to all three switches

next came the two switches for the laser on and off and laser test wich.

These are very different to the originals. As five pins instead of 2 pins as you have NC, NO, C, +12 and Ground.

- NC = Normally Closed

- NO = Normally Open

- C = Common

- +12 = + 12 volts in this case using 5v

- Ground = ground side of swtich.

Now to wire these up, I to the two red wires for the on and off made a jumper cable so +12 and NC are wired to red cable one side and ground and common are wired to the other side of the switch. For the test button, I used the +12 and ground off the on/off switch to light the button when it’s on I then used the two original black wires on NO and C.

Adding the screen, this is held in by 4 x m3 x 25 mm screws I fed the screws through the panel and added 2 x m3 nuts behind it to act as spacers on each screw. I then fitted the panel and held it in place with further 4 x m3 nuts. 2 ribbon cables were then installed in ports exp1 and exp2 this I will connect to new controller board shortly.

Rotation of the Power supply I removed the four screws holding the existing power supply in place. I then attached the new bracket in place then using original fixing holes bolted power supply back to the bracket. I then aligned it and marked where I would need to drill then drilled 2 x 4.5 mm holes and mounted the bracket tightened down with bolts and butterfly nuts.

I then wired in 5v & 24v Power supply for lighting and laser sight. In a previous post, I had added LED tape to the inside of the cutting area and control panel area of the laser machine. I soldered some more wiring on to get it to reach the newly installed power supply I also added the two wires for the laser sight they are both switched on using the light switch on the control panel.

Instaling the laser sight:

You will need an upgraded cutting head fixing plate. You will need to unscrew the three screws that hold the plate to the laser carriage. Remove cutting head from the plate and install into the new one. Then reinstall back on the laser carriage. After that placed two bolts through the bracket and aligned the laser with test mark, I had made on the material. I tightened bracket to stop movement I then unplugged laser and threaded wiring thought cable chain and plugged into 5v power supply job done.

Note: my eBay brought plate only let me fit 2 screws back in will have to modify the slot to fit the 3rd screw as out by 1 mm.

Installing C13 Panel for the rear of machine:

As requested here’s the link to my remixed c-13 panel get it here

I have decided to remove the 2 plug sockets from the rear of the machine as they are positioned badly the bottom one is very hard to plug in to. after looking through Thingiverse I found this simple C13 panel I remixed it slightly by adding some text for the aux equipment I wanted to run out of it. the air-assist is connected to a switch on the control panel whereas the water pump and fan vent run when the machine is switched on.

I started off by removing the 2 plugs I then got my tin snips and removed the metal connecting the plug holes I then fitted the plate and using an m3.5 drill bit I drilled the holes on either side of the c13 connector.

After that using terminal block connected the wires to the back of the c13 connectors. I also added power for the additional 24v power supply for the stepper drivers and new controller board as the 2 sockets power on with power switch.

I then screwed the panel down using 6 x m3 screws and nuts.

Installing wire temp mesh bed:

I went to a local DIY shop and picked up some 50×50 cm fine diamond mesh. I used the original alloy bed to make measurements I then cut the sheet down to the same size using side cutters. I used 3d printed adapters on the top of each fixing point before installing the bed I then used original screws to reattach it to the bed.

as I know my optimal focus point is approximately 8mm off the bed I inserted spacer discs that I have printed to a hight of 8mm so my 3mm materials cut like a hot knife through butter.

Installing the Cohesion3D Mini K40 Upgrade kit:

Now that all upgrades have been installed to my printer and I am happy everything is working. I am going to go ahead with installing the Cohesion mini board and install the screen for time being I will be doing more upgrades for adjustable bed and rotary tool in the future but for now the board and the screen will do.

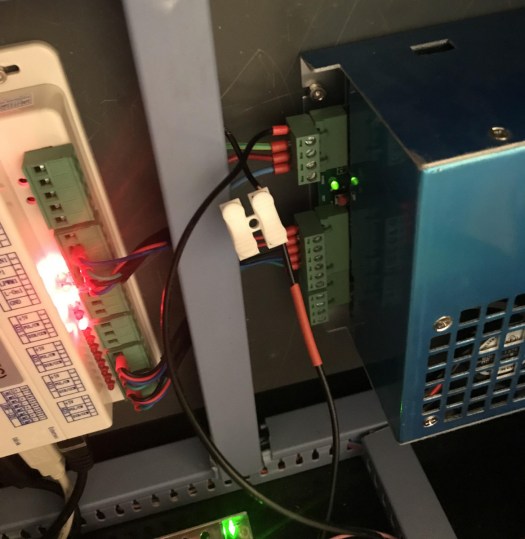

First of all, I removed the 3 nuts and bolts holding control board plate in place,

I then unplugged the 3 connections from the board 1 ribbon cable two Molex connectors I then undid the nuts holding M2nano board in place after this I installed new board redid up the nuts.

I also added holes and fixings for the 2 stepper drivers so I can add rotary attachment and z table at a later date. I will only wire up the for the rotary attachment atm as still unsure if I will use my light object z table.

I then added additional wiring for stepper driver and connected up to the 24v power supply and doe the control board.

I connected the screen connector and plugged in the first exp2 then esp1 as the guide explains. I inserted the micro sd card as well I then reconnected all cables.

I am having issues with the screen I have ordered a replacement. I am receiving support from C3D hopefully have it up and running soon.

need to tidy up the wiring at some point soon but for the moment I want to test.

time to test, I have already installed Lightburn on my pc. to turn on my machine and see that it works. right all powers on and test button works.

It’s alive.

Next project for the k40:

Making a 3d printed Z hight adjustable bed off Thingiverse as the electric one I have brought is too small for my liking.

3d printing has begun about 20hrs to go.

Parts have been ordered so once they all come in I will be building this. will be adding a rotary attachment for doing round projects.

Rotary Attachment incoming from China via aliexpress.(currently in Germany should be with me by Wednesday according to FedEx) Now in part 1 of review is up now link here.

after that is done will be the end of my mods on the k40 for the time being.

Next Website Project CNC machine Enclosure:

This has been started Link Here

Like this:

Like Loading...

You must be logged in to post a comment.