As i have had some issues with getting my lightburn camera to align and recognise all registration marks in calibration and alignment set up. I have decided i am going to add a better light source and see if this will improve the process.

first of all, i am going to identify current strip is running 12v or 24v or 240v so out with my trusty voltmeter. As i can see a 3 prong pin looks very similar to some i have seen on Amazon or aliexpress so once i know voltages i can look at my options. i am hoping its 12v as then will be as easy as buying a connector and digging out some led tape.

high voltage led strips so i have decided to go down the route of low voltage dimmable LED’s as cheap easy to fit.

As a maker, i had all the bits, apart from the led tape that i needed to order. So I found a cheap 5m kit off amazon prime as time is always an issue when ordering from China.

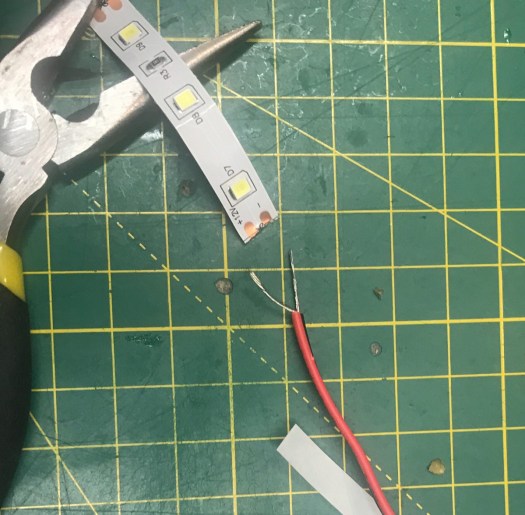

I have 50m of red and black, led wiring cable in my stock of parts. I started off by stripping the wiring off both wires and tinned them, I then took used my flux pen to clean up the terminals and added solder to both solder pads. I then soldered the wires to the pads.

I then used isopropyl alcohol to clean the area i was going to stick the tape to. I started bottom right worked the tape around the edge of the bed above the rim. Till it had gone around the bed.

i added cable tabs to so i could keep some cable management i then threaded the wiring through the laser and out through a hole in the floor i then wired up a d 2.1 x 5.5 female connector to the end of the cable.

this is where i connected the dimmer switch and plugged the lighting into the mains

The end result looks good and hoping will cure my lightburn camera issues.

Next up:

I am going to see if i can now calibrate properly using the lightburn camera. if that works fine, I will design a slimline camera mount for the lightburn camera. As an issue with current cameras mount is the laser head hits is when running on the bottom of the printer.